![]()

Electric Vehicle Thermal Management Solutions

Electric vehicle thermal management is critical in terms of performance, longevity, and safety. Electric vehicle batteries are susceptible to fluctuating temperatures caused by both internal and external factors and can become damaged or degraded if exposed to temperatures outside their optimal range. This is especially relevant when operating in extreme temperatures or during rapid charging. Senior Flexonics battery thermal management plates are designed to maintain temperatures, ensuring that safety, performance, and battery life are optimized.

ELECTRIC VEHICLE BATTERY COOLING PLATES – THERMAL MANAGEMENT

ELECTRIC VEHICLE BATTERY COOLING PLATES – THERMAL MANAGEMENT

Heat is created when either charging or discharging batteries which can lead to reduced life or catastrophic failure at high temperatures. Heat is generated from the internal resistance of the battery which is called Joule or Ohmic heating. The current standard is to use liquid cooling. These water-glycol coolants can either be passed in between cells, battery packages or the usage of cooling plates to manage the heat being generated. Typical cooling plate designs have a large temperature gradient across the heat exchanger surface offering inconsistent battery cooling. Consistent cooling across battery cooling plates is critical to manage these temperatures. Senior Flexonics has developed a unique two pass battery cooling plate design that provides a maximum of 3°C degree delta across the entire contact surface. Cooling plates are constructed from a variety of materials including stainless steel and aluminum. We are developing cooling plates and fluid conveyance solutions in partnership with well-known truck and passenger car manufacturers.

HEAT SINKS FOR INVERTERS (IGBTs) – COOLING EV ELECTRONICS

HEAT SINKS FOR INVERTERS (IGBTs) – COOLING EV ELECTRONICS

Inverters transfer power between the motors and batteries and are one of the critical components in an electric vehicle. The inverter converts DC to AC when power is required to drive the electric motors and converts in the opposite direction during regenerative braking. The main component inside the inverter is the IGBT (insulated gate bipolar transistor), and it generates heat. An effective method of cooling the IGBT is through a liquid cooled heat sink.

Inverters transfer power between the motors and batteries and are one of the critical components in an electric vehicle. The inverter converts DC to AC when power is required to drive the electric motors and converts in the opposite direction during regenerative braking. The main component inside the inverter is the IGBT (insulated gate bipolar transistor), and it generates heat. An effective method of cooling the IGBT is through a liquid cooled heat sink.

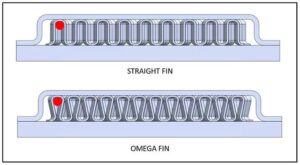

Our heat sink features our proprietary “Omega” fin design. It is available in both aluminum and copper depending upon the customer’s requirements. Cooling of IGBT’s also has become critical in maintaining reliability and efficiency. These new EV chill plates enhance thermal performance without plugging because the unique shape creates more surface area than a typical straight fin, while still allowing the same sized particles to pass without plugging.

Senior Flexonics is a leader in EV thermal management and fluid conveyance from our experience with ICE power train systems. We are an established industry partner that offers complete engineering, in house testing and large global production capabilities.

Omega Fin Heat Sink – Increasing Performance

Senior Flexonics’ “Omega Fin” design was created in order to solve the challenge of increasing the performance of the heatsink while maintaining a minimum gap for particle size. The Omega fin works by increasing the amount of fin surface area inside the heatsink.

Heat Sink Design

The IGBT heatsink is made up of a base plate, cover plate, and fin. Coolant enters through a spigot in the cover plate and then flows across the fin and exits through the spigot on the opposite side. The base plate sits on top of the IGBT to allow for surface contact cooling.

Omega Fin Design Benefits

- Developed to increase performance while maintaining a minimum gap for particle size

- More surface area can be utilized with the Omega fin

- Straight fin design has 9 fins while the Omega fin design has 12 fins a 33% increase

Electric Vehicle Thermal Management Resources

Please feel free to download our detailed whitepaper about our proprietary approach to heatsinks entitled: EV Thermal Management Improved by Unique Fin Design – Author: Brian Costello – Advanced Development Engineer – Senior Flexonics

Get Immediate Access to the Charged Virtual Conference and our Hybrid and Electric Vehicle Presentation entitled: Innovations in Electric Vehicle Cooling Technology

HOSE, TUBE, AND PIPES FOR EV – COOLANT FLUID HANDLING

HOSE, TUBE, AND PIPES FOR EV – COOLANT FLUID HANDLING

Battery cooling plates and electronics cooling require hose, tubing and pipes to transfer gas and liquids. Senior Flexonics has decades of experience supplying reliable fluid conveyance solutions and are currently working with many of the worlds leading brands supplying battery coolant pipes, electric motor coolant pipes and gearbox air pipes to name a few. All configurations can be supplied with all required fittings and connectors to meet your quality standards.

Battery cooling plates and electronics cooling require hose, tubing and pipes to transfer gas and liquids. Senior Flexonics has decades of experience supplying reliable fluid conveyance solutions and are currently working with many of the worlds leading brands supplying battery coolant pipes, electric motor coolant pipes and gearbox air pipes to name a few. All configurations can be supplied with all required fittings and connectors to meet your quality standards.

HEV FLEX – WASTE HEAT RECOVERY and HEAT RETENTION

HEV FLEX – WASTE HEAT RECOVERY and HEAT RETENTION

Extending EV ranges using Hybrid solutions requires maximum efficiency and waste heat recovery and heat retention. Senior Flexonics provides many solutions for the HEV market around the globe to many leading brands.

Extending EV ranges using Hybrid solutions requires maximum efficiency and waste heat recovery and heat retention. Senior Flexonics provides many solutions for the HEV market around the globe to many leading brands.

Ask An Expert about Electric Vehicle Thermal Management

How can we be of service? Please let us know if you prefer to speak to an Engineer or a person from sales.