Ask An Expert

How can we be of service? Please select the correct icon below to direct your request to the right person. Please let us know if you prefer to speak to an Engineer or a person from sales.

Necessity is the Mother of Invention

Innovations are the Descendants.

One hundred years is a long time and Senior Flexonics has had many firsts during the past century. Flexonics was founded in the time when streets were lit with gas lamps. With the advent of the automobile, new drivers and their inevitable accidents not only gave rise to the auto insurance industry, but also the need for safer infrastructure. Streetlamps, needed for safe nighttime travel, had the unintended consequence of a catastrophic explosion when struck by a new driver. Necessity is the Mother of Invention. To solve this hazard Senior Flexonics created a flexible, stainless steel hose that would run through the gas light posts and shut off the gas line if the post was hit by a car. Explosions ceased. This innovation saved lives and property.

Fast forward a few decades, the space race was on. Wernher von Braun, the famous rocket scientist, needed durable metal bellows for the Saturn V rocket which was used for the Apollo space program. These giant expansion joints in the rocket booster, eight, ten or twelve feet in diameter, helped bring us to the moon and were designed, prototyped, validated and produced in the Senior Flexonics Bartlett facility. This commitment to developing solutions continues today as new challenges present themselves.

Necessity for a Cleaner Environment – Gas & Diesel Vehicles getting Cleaner and More Efficient

Senior Flexonics developed a unique metal bellow to create leak-tight exhaust flex systems instead of the ball joint system, the standard practice at the time. This innovation took up the different motions/movements between the engine and the exhaust system while at the same time helping our customers keep a leak tight exhaust to meet emissions legislation.

SOLUTIONS FOR ALL TYPES OF COMBUSTION ENGINES

Whether it is a Diesel, Gasoline or Natural Gas Engine, our extensive range of products can be customized to your exact specifications.

- Exhaust Gas Circulation (E.G.R.) and waste heat recovery for all types of combustion engines (Diesel, Natural Gas and Gasoline).

- Flexible metal bellow solutions to manage temperature and movement in all types of vehicles ranging from personal transport to on and off highway commercial vehicles.

- Diesel and gas fuel delivery systems including common rail and liquid conveyance for all types of cooling requirements.

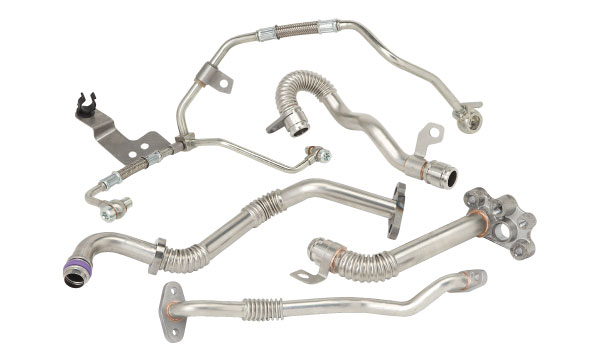

- Turbo Oil Feed and Drain Tubes.

Commercial vehicles presented a different clean air challenge. While accounting for only 4% of the vehicles on the road, they were responsible for 25% of the emissions. Capturing the heat from wasted emissions and reintroducing this into the engine flow is one method to reduce that impact. Although well intended, earlier EGR Cooler designs were prone to various problems as metals were exposed to extreme temperature ranges and the inherent expansion and contraction. To address this, Senior Flexonics engineers listened to our customers’ needs, and applied their thermal management and heat exchanger experience to develop a durable, million-mile Exhaust Gas Recirculation (EGR) cooler that would not only reduce emissions, but drastically reduced our customer’s warranty claim burden.

From these applied lessons in thermal management and heat recovery, we are now ready to address driver concerns about the reliability, efficiency and range of electric vehicles – How far can I drive before I must charge, and will there be a place to do so?

Necessity for Electric Vehicle Improvements – Further and Faster

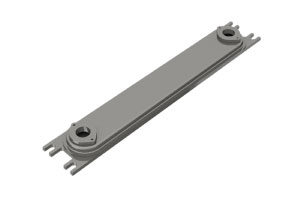

Thermal management in electric vehicles is critical in terms of performance, longevity, and safety. Electric vehicle batteries are susceptible to fluctuating temperatures caused by both internal and external factors and can become damaged or degraded if exposed to temperatures outside their optimal range. This is especially relevant when operating in extreme temperatures or during rapid charging. Senior Flexonics battery thermal management plates are designed to maintain temperatures, ensuring that safety, performance, and battery life are optimized.

HYBRID VEHICLE ADVANCEMENTS

Our extensive thermal management experience with both I.C.E and electric products uniquely positions Senior Flexonics to serve these types of vehicles.

- Battery cooling plates for electric and hybrid vehicles to maintain critical temperature thresholds.

- Highly efficient inverter cooling technologies to protect IGBTs.

- Waste heat recovery solutions and heat retention to extend vehicle ranges.

- Flexible metal bellow solutions to manage temperature and movement in all types of vehicles ranging from personal transport to on and off highway heavy duty vehicles.

- Tubes / pipes for all types of engine systems ranging from the transfer of gases to liquid conveyance for all types of cooling requirements.

- Electric motor and buffering cooling tubes/pipes.

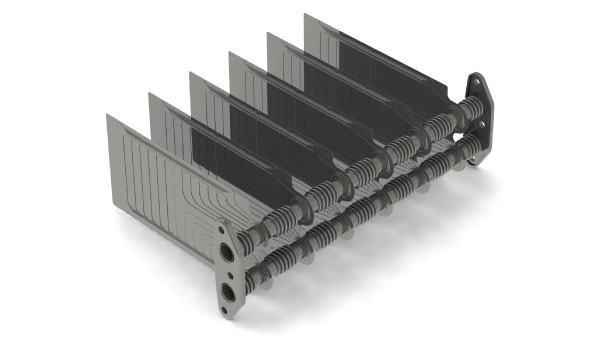

Senior Flexonics is always researching the best ways to keep electronics cool. The power inverter is one of the critical components in an electric vehicle. The inverter converts DC to AC when power is required to drive the electric motors and converts in the opposite direction during regenerative braking. The main component inside the inverter is the IGBT (insulated gate bipolar transistor), and it generates heat. An effective method of cooling the IGBT is through a liquid cooled heat sink. Our heat sink features our proprietary “Omega” fin design. It is available in both aluminum and copper depending upon our client’s specifications. These new EV chill plates enhance thermal performance without plugging because the unique shape creates more surface area than a typical straight fin, while still allowing the same sized particles to pass without plugging.

ELECTRIC VEHICLE ADVANCEMENTS

Thermal management products for Electric Vehicles.

- Battery cooling plates to maintain critical temperature thresholds.

- Highly efficient heat sinks for the cooling of inverters to protect IGBTs.

- Waste heat recovery solutions to extend vehicle ranges.

- Tubes / pipes for all types of cooling requirements.

Necessity to Deliver Energy – Innovations to help deliver that power

Operations utilizing turbines, fuel cells, solar and vacuum/semiconductors require complex assemblies. Our Engineering resources have knowledge of specialized high-temperature alloys and manufacturing processes that require forming, welding, brazing, soldering, bending and machining of these materials. For our power generation customers, we manufacture custom heat exchangers, flexible metal tubing and hose, fuel nozzle bellows and recuperators.

Our stationary Fuel Cells (SOFC and PEM) and Battery Farm component advancements have found applications for cloud-based data centers. As they are usually located in remote areas many rely on generating their own electricity through fuel cell technologies or battery farms. Fuel cells and battery farms all require consistent temperatures to prevent thermal loading. The utilization of heat exchangers to maintain the proper temperature range.

ENERGY SOLUTIONS

We support many different energy technologies that require components customized to exact specifications.

- Nuclear

- Electric

- Solar

- Fuel Cell – Stainless Steel sub-assemblies and heat exchangers.

- Vacuum/semiconductors.

- Utilities – Vacuum Interrupters, Vacuum Breakers for fault detection.

Necessity to Stay Ahead – Innovations to meet industry challenges

Oil and Gas I Chemical Processing I Petrochemical and Refining I Heat Exchangers I Power Generation I Medical/Pharmaceutical I Electronics

Industrial markets all have requirements to meet the challenges set before them. For decades, we have continually invented new products to meet each of their specific and unique constraints. To support the development of these innovations we offer extensive analytical testing capabilities as well as rapid prototyping. These innovations are then validated against physical testing and computer modelling to predict the product’s lifecycle. Once accepted and green lighted for production, our high and low volume manufacturing abilities kick in to produce a wide range of products such as complex bellow assemblies that require forming and high precision machining. Our thermal management experience with Heat Exchangers is yet another example of our capabilities that span across a variety of industrial markets as detailed below.

INDUSTRY – COMPLEX BELLOWS SUB-ASSEMBLIES

DEFENSE / MILITARY, FOOD & BEVERAGE, FUEL CELLS, HVAC / R, INDUSTRIAL, MEDICAL, OIL & GAS, UTILITIES

Our metal bellows, thin walled expansion joints and tubing products can be customized to your market specifications. We deliver precision assemblies for life saving medical systems, durable parts to enable our military to fulfill their mission, extremely heat resistant components to research resources deep in the earth, and reliable products to mitigate infrastructure down-time.

- Defense / Military – Nuclear valve secondary containment. Gate, Globe and Pressure relief valve applications. Military vehicle bellows.

- Food & Beverage – Process heat exchangers, expansion joints and sub-assemblies.

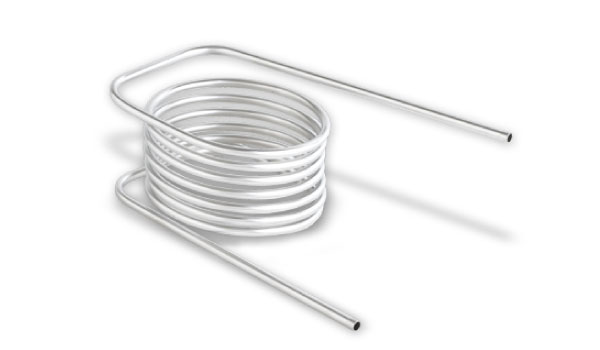

- HVAC / R – Sub-assemblies, heat exchangers, flexible tubing, gas feedlines, and compressor connections.

- Industrial – Compressor and pump flexible connections, Expansion Joints, Aneroid assemblies.

- Medical – Blood heat exchangers, adult/infant oxygenator bellows, coronary perfusion and whole-body perfusion heat exchangers, Cryosurgical ablation probes.

- Oil & Gas – ESP Compensators and Artificial Gas Lift valve bellows.

Oil and Gas

Senior Flexonics supports both upstream and downstream activities in the oil and gas industry from deep sea drilling to processing. To support upstream industries, we manufacture precision components for valves, cages and Gas Lift Bellows. Downstream activities supporting refinement / processing include specialized expansion joints and on-site services to maintain production in emergency situations such as Clam Shell repairs of bellows elements. These can often be done online, helping a facility avoid a costly shut down.

Chemical Processing

As a world leader in the design of Catofin expansion joints, Senior Flexonics continues to develop processes while working closely with licensors and customers to identify needs. These expansion joints must work under the stress of incredible heat, movement and velocity, and have the capability for advance warnings for security.

Leak detection is paramount in plant piping and sometimes measurement gauges are not accessible or readily visible. Senior Flexonics “Red Tops” detect leaks in sections of piping without having the control panel in sight. This keeps the plant “online” and secure with numerous check points available.

Petrochemical and Refining

Equipment can be maintained by the Senior Flexonics team through on-site services such as surveys or emergency repair. By partnering with these companies and sharing records and reports, an outside eye can be invaluable in finding gaps and introducing efficiencies to implement. Whether in expansion joint inspection, petrochemical installation, or existing equipment repair.

Medical/Pharmaceutical/Food and Beverage

Medical devices demand strict manufacturing protocols for cleanliness. These complex assemblies vary greatly and may require specialized processes in their manufacture such as the union of dissimilar materials (Inconel to ceramic). Senior Flexonics has a long-established reputation for excellence producing these advanced components for life saving equipment that includes: blood heat exchangers, adult/infant oxygenator bellows, coronary / whole-body perfusion heat exchangers, and cryosurgical ablation probes. In the pharmaceutical industry we provide process heat exchangers, expansion joints and sub-assemblies to many well-known companies that produce various caplets, tablets, and liquid formulations.

Electronics

Innovations in electronics such as vacuum capacitors are used in high voltage applications. This variable capacitor is used for many purposes that require tuning, such as matching a network in the fabrication of semiconductor chips and flat panel displays. This unique design uses a high vacuum as its dielectric instead of air or non-conductive materials. Some of the most common applications are antenna couplings, semiconductor wafer fabrication, RF matching circuits, Pulse shaping circuits, Power amplifier tank circuits, and Non-magnetic circuits for MRI. Benefits of their use include long life and high reliability contained within a smaller package size and lower weight.

Necessity of Hydrogen Eco-Systems

Many economic, demographic, social, and sustainability questions have demanded change on energy usage and mobility. From these megatrends, new technologies are being introduced, setting a new course that will require future technological breakthroughs.

HYDROGEN ECO-SYSTEM SOLUTIONS

Thermal Management and Fluid Conveyance expertise to assist with industrial scale Hydrogen electrolysis, storage, distribution and hydrogen powered vehicle systems.

- Complete sub-assemblies consisting of – Heat Exchangers, Expansion Joints / Bellows, Corrugated Hose and Tubing

- Materials expertise – Dedicated Engineering research with a wide range of materials including specialty stainless steels

- Projects – Energy Plants, Hydrogen Production, Refueling Stations, Fuel Cells and Hydrogen Powered Vehicles

- Locations – Global Manufacturing Footprint with R&D facilities in North America and Europe

Your Organization’s Next Project Necessity.

Does your organization require thermal management expertise for a new product innovation? Senior Flexonics has developed bellows systems which can withstand the extreme low temperature of liquid helium at -452 F as well as extreme heat environments of over 2000 F. Materials experience includes brass, bronze, beryllium copper, 300 series stainless steel, titanium, Monel®, Inconel®, Hastelloy®, and other nickel alloys. All products developed by Specialty Products are of the highest quality and durability and service markets ranging from Medical, Semiconductor, Valves, Oil & Gas, HVAC, and Food & Beverage to name a few. We invite you to speak with Engineering about your next specialty product.

SPECIALTY PRODUCTS

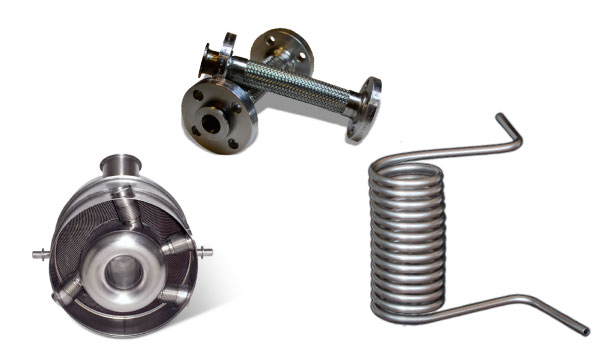

Senior Flexonics provides highly customized thermal management and fluid conveyance solutions to our clients developing new products. Working with our clients we provide engineering, validation, and manufacturing of complex metal bellows, flexible hose and tubing assemblies that require forming, welding, brazing, soldering, bending, machining and assembly.

- Medical Devices – Medical Bellows, Cooling Coils and Flexible Tubing

- Semiconductors – Vacuum Capacitors, Vacuum Interrupter/Breaker and Bellows Assemblies Connectors

- Oil and Gas – Upstream, Midstream and Downstream Bellow Assemblies and Seals

- Valves – Reliable Long Life Gate, Globe, and Pressure Relief Valves

- HVAC – Expansion Joints, Flexible Connectors, and Safety Valve Connectors

- Pharmaceutical / Food and Beverage Production – Process Heat Exchangers, Metal Bellows, Braided Hose, and Corrugated Tubing

Necessity to change – Seeing opportunities, innovating and creating inventions for our customers.

No one knows what the future holds. However, necessity will continue to be the Mother of invention. To prepare for what comes next, Senior Flexonics is gathering purpose-driven talent, leveraging advanced proactive engineering, and collaborating with our customers to create value for all stakeholders. For well over 100 years, Senior Flexonics has developed innovative metal bellows sub-assemblies, tubing and thermal management solutions to meet and/or exceed our customers’ needs and requirements. By applying these competencies to our customers’ challenges, Senior Flexonics has evolved into a multi-industry corporation spanning the globe. We invite you to learn more about our company’s innovations and the unique markets we serve.

The World of Senior Flexonics.

Senior Flexonics Locations

Senior Flexonics Canada

134 Nelson Street West

Brampton, Ontario L6X 1C9

Canada

T: +1 800 267 1975

T: +1 905 451 1250

F: +1 905 451 1315

E: sales@flexonics.com

W: www.flexonics.com

Senior Flexonics Cape Town

![]()

![]()

PO Box 476

Eppindust, Cape Town 7475

South Africa

T: +27 21 5325300

F: +27 21 5325310

E: info@flexonics.co.za

W: www.flexonics.co.za

Senior Flexonics Japan

![]()

![]()

![]()

![]()

![]()

![]()

Building.9F 1-10 Omori-Kita 1-chrome, Ota-ku, Tokyo 143-0016

Japan

T: +81 3 5767 7338

M: +81 90 2421 5314

E: Senior@ezaki.co.jp

GA Precision

![]()

![]()

![]()

5215 West Airways Avenue

Franklin, Wisconsin 53132

U.S.A.

T: +1 414 423 6400

W: www.ga-precision.com

Lymington Precision

![]()

![]()

Gosport Street

Lymington, Hampshire

SO41 9EE

UK

T: +44 (0)1590 677 944

E: rmoore@lymingtonprecision.co.uk

W: www.lymingtonprecision.co.uk

Senior Flexonics Bartlett

![]()

![]()

![]()

![]()

![]()

![]()

300 East Devon Avenue

Bartlett, Illinois 60103

U.S.A.

T: +1 630 837 1811

F: +1 630 837 1847

E: gblanchet@seniorflexonics.com

W: www.seniorflexonicsusa.com

Senior Flexonics Crumlin

![]()

![]()

![]()

![]()

![]()

![]()

Pen-y-Fan Industrial Estate

Crumlin, NP11 3HY

UK

T: +44 (0)1495 241500

F: +44 (0)1495 241521

E: info@seniorflexonics.co.uk

W: www.seniorflexonics.co.uk

Senior Flexonics Kassel

![]()

![]()

![]()

![]()

![]()

![]()

Frankfurter Strasse 199 D-34121

Kassel, Germany

T: + 49 561 2002 0

F: + 49 561 2002 111

E: service@seniorflexonics.de

W: www.seniorflexonics.de

(Senior Flexonics) SF Pathway Metroflex

![]()

![]()

29 Lexington St.

Lewiston, ME 04240-3511

U.S.A.

T: +1 207 784 2338 ext.3362

E: crollins@sfpathway.com

W: www.sfpathway.com

Senior Flexonics New Delhi

![]()

Plot No.89, Sector 8

IMT Manesar, Gurgaon – 122050 (Haryana)

India

T: +91 124 438 7704

F: +91 124 438 7703

E: sipl@seniorauto.co.in

W: www.seniorauto.co.in

Senior Flexonics Olomouc

![]()

![]()

![]()

Prumyslova 9

Olomouc-Holice

779 00

Czech Republic

T: + 420 585 151 180

F: + 420 585 151 172

E: mgrimm@seniorflexonics.cz

W: www.seniorflexonics.cz

Senior Flexonics Wuhan

![]()

![]()

![]()

![]()

T: +86 27 59622048 / +86 27 852069

F: +86 27 59622049

Wuhan, China

E: yuki.wang@ppmsolution.com

(Senior Flexonics) SF Pathway

![]()

![]()

![]()

2400 Longhorn Industrial Dr.

New Braunfels, Texas 78130

T:+1 830 629-8080

F:+1 830 629-6899

E: edavis@sfpathway.com

W: www.sfpathway.com

Senior Flexonics Saltillo

![]()

![]()

![]()

Parque Industrial La Angostura

KM 4.5 Carretera Saltillo-Zacatecas

C.P. 25315 Saltillo, Coahuilla

Mexico

E: gblanchet@seniorflexonics.com

W: www.seniorflexonicsusa.com

UPECA Senior Flexonics Tianjan

![]()

![]()

![]()

![]()

UPECA Engineering (Tianjin) Co., Ltd.

T: +86 22 59611718 Ext. 207

F: +86 22 59611719

Tianjin, China

E: tracy.he@upeca.com.cn